Sandwiches come in many combinations and flavours. Sourdough with hummus and avocado, rye with pastrami and pickles or a couple of slices of cheap white bread filled with butter and hot chips. But the sandwiches we’re talking about today are sandwich panels or insulated panels. Insulation clad on both sides with either metal, wood or other cladding materials.

Fast and easy to install insulated panels create great outcomes for clients and installers. Providing cheaper and quicker install times and buildings that stay cool in the summer and warm in the winter. With the right tools, installing insulated panels can be a breeze.

Taking The Heavy-lifting Out Of Installation

The days of man-handling large and cumbersome panels on job sites is over with tools like the CLAD-BOY® from Aero Lift. Made in Germany, Aero Lift’s goal is to make workplaces safer. Faster installation doesn’t equal less safety with the CLAD-BOY® being fully compliant with safety standard EN-13155. With a rechargeable battery that lasts up to 100 work cycles, a built-in charger, and an optional second battery, the CLAD-BOY® just keeps on trucking. It’s built to last in the heat and the cold, so it’s great for the variable climes we enjoy in New Zealand and Australia. It keeps panels in tip-top condition and comes with its own space-saving travel case, making transportation to and from site easy. Want to elevate your install work flow? Give CLAD-BOY® a go.

Spark-free Cutting

Summer’s are not getting any cooler, and the risk of fire on construction sites is not going anywhere. Metal-clad insulated panels require a method of cutting that is spark-free. Enter the Trumpf TPC 165 and the Jepson panel cutter. Designed for polyurethane and polyisocyanurate sandwich panels, the Trumpf TPC 165 panel cutter can cut through insulated panels up to 165mm thick with ease and precision. The integrated chain lubrication system stops the chain from heating up whilst in use and it comes with a 5-year warranty. The Jepson SHDC 8320 insulated panel cutter offers another solution for spark-free cutting in the form of a carbide-tipped saw blade with low-burr saw action. And its integrated chip collector helps keep workspaces tidy. It’s designed to cut a variety of materials up to a total depth of 120mm.

Making Sure The Sandwich Is Sealed

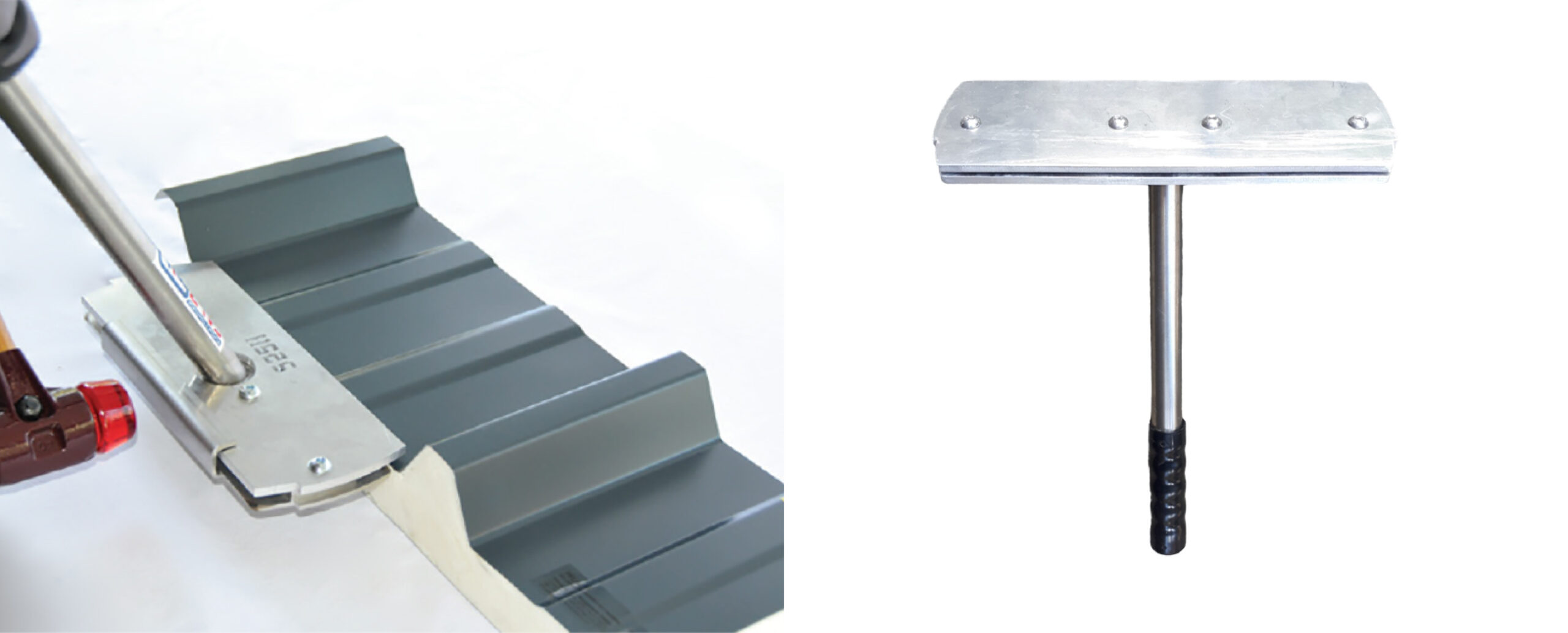

Like a well-made toastie, an insulated panel needs to be sealed to keep all the cheesy goodness inside. Did I say cheese? I meant insulation. The S-Bender Stop End Tool bends sandwich panels at the ridge and eaves for proper drainage and water ingress prevention. This durable but lightweight device can be used with different adapter heads, including the T-bender Stop End Tool, providing 360° water ingress protection. Both are designed by us in collaboration with our supplier.

The Perfect Sandwich

Insulated panels are a great way to build efficiently with client satisfaction in mind. And much like a reliable bit of multigrain sandwich bread, specialised tools are the structure that holds a good workday together.

Want to learn more about our range of insulated panel products? Email us today at order@fribesco.com.

Comments (0)