The Fully Automatic Compact Profiling Machine for small and medium-sized Production

The Profil Profi PP3000 is Herburger’s premium profiling machine, built for series production. It combines robust engineering with advanced automation to deliver maximum efficiency and precision.

Simple and easy to use for any roofing-cladding company.

Machine Information

The Herburger Profil Profi PP3000 is more than just a profiling machine — it’s a complete production solution for small or medium-sized roofing and cladding companies.

Compact yet powerful, the PP3000 combines user-friendly automation and robust durability to make blank sheet metal profiling faster, easier, and more profitable.

Operation

- Operating the PP3000 is simple and efficient. The operator feeds the sheet metal into the machine, where the fully automatic drive takes over. Width adjustments are quick and easy, thanks to the trapezoidal spindle system on the side of the machine, allowing processing of sheets from 250 to 820 mm.

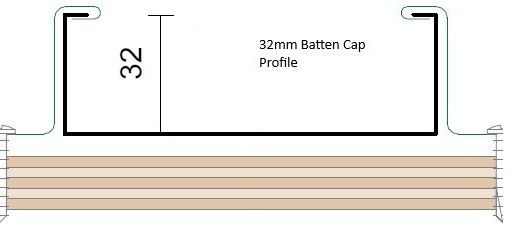

- Once material is in place, the PP3000’s hardened rollers shape the blank into precise standing seam profiles of 32 mm on both sides. The integrated cutting units handle both width (manually adjustable) and cross-cutting automatically, controlled by a Siemens system that allows you to pre-select the exact quantity and dimensions required. With speeds of up to 15 m/min, the machine delivers consistent, repeatable results with minimal manual intervention while processing blank steel sheets.

Integrated Round Bending Unit

Integrated curving: The round bending unit works immediately after the initial profiling process.

Adjustability: The radius of the curve can be slightly adjusted to meet project specifications. Note, this is only to form a slight curve on the profiled panels

Application: Herburger’s profiling machines are specialized for standing seam technology, used on roofs and facades. The round bending unit expands its capabilities to produce slightly curved versions of these profiles.

Technical data

FEATURES

- Everyday Benefits in Production – Commercial advantages

- Ease of use / productivity: Full automation and quick adjustments mean even new operators can produce accurate profiles quickly and process more material in less time.

- Flexibility: Suitable for galvanized steel, zinc, stainless steel, copper, and aluminium sheets — giving you versatility across projects.

- Safety First: The protective cover is equipped with a safety switch that automatically shuts down the machine when opened — guaranteeing safe operation at all times.

- Compact design: Despite its industrial performance, the machine takes up minimal workshop space and sits on caster wheels, making it convenient to shift around coil storage systems or easily stored away.

- Consistent Quality: Precise roller technology and Siemens-controlled cutting optimize material usage by nesting profiles closely together. This efficiency results in significantly lower material waste compared to traditional cutting/profiling methods.

- On-site and off-site production: Mobile roll forming machines can be brought to a job site to produce components on demand, reducing transport costs. Alternatively, manufacturing components off-site in a controlled environment offers peak efficiency.

FRIBESCO’s reasons:

Why Choose the PP3000?

✅ Fully automatic operation for maximum productivity

✅ Stepless width adjustment for unmatched flexibility

✅ Robust, hardened roller technology for precision and durability

✅ Suitable for all standard roofing materials

✅ Compact design, easy to integrate into production workflows

The Herburger Profil Profi PP3000 gives professional profilers the edge: faster throughout, consistent accuracy, and long-term reliability.

📞 Contact us today to discuss your requirements and arrange a demo.